Setup & V-Blocks

Setup and V-blocks are important tools used in various machining and precision work applications. Here's an overview of setup blocks and V-blocks:

Setup Blocks:

- Purpose: Setup blocks are used to provide a precise and consistent reference height for setting up workpieces or tools on machine tables or surfaces.

- Design and Construction: Setup blocks are typically rectangular blocks made of hardened steel or other rigid materials. They are accurately machined to specific thicknesses and are often available in sets with varying thicknesses.

- Usage: Setup blocks are placed underneath workpieces or tools during setup to establish a known and repeatable height. They are commonly used in milling, drilling, and grinding operations to ensure accurate positioning and alignment of workpieces or fixtures.

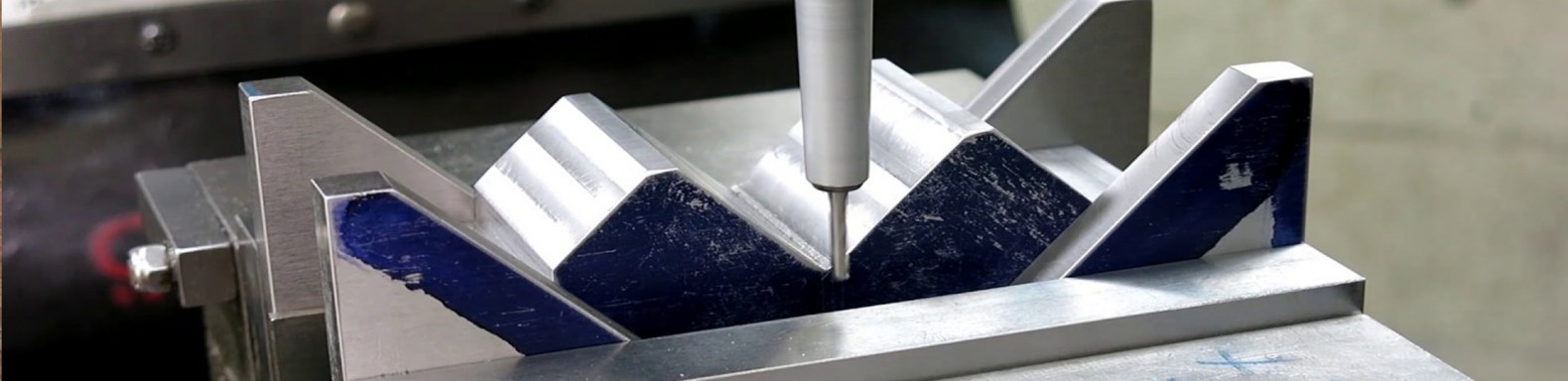

V-Blocks:

- Purpose: V-blocks are used to hold cylindrical or round workpieces securely for various machining, inspection, and assembly operations.

- Design and Construction: V-blocks consist of a V-shaped groove or channel that securely holds the workpiece. They are typically made of hardened steel and have a precise V-angle to match the diameter of the workpiece.

- Usage: V-blocks are placed on a flat surface or mounted on a machine table. The workpiece is placed in the V-groove, providing stability and alignment. V-blocks are commonly used in tasks such as drilling, milling, grinding, and inspection of cylindrical parts.

Benefits of Setup Blocks and V-Blocks:

- Accuracy: Setup blocks and V-blocks provide precise reference surfaces and alignment, ensuring accurate positioning and measurements during machining or inspection operations.

- Stability: These tools offer stability and secure clamping of workpieces, minimizing movement and vibration during machining processes.

- Versatility: Setup blocks and V-blocks can be used for various workpiece shapes and sizes, providing flexibility in different applications.

- Efficiency: By using setup blocks and V-blocks, the setup and alignment process becomes quicker and more efficient, reducing the time and effort required for accurate machining operations.

Overall, setup blocks and V-blocks are essential tools in machining, fabrication, and precision work. They enable accurate positioning, alignment, and secure holding of workpieces, contributing to the quality and precision of the finished products.

-PhotoRoom.jpg)