Measuring Stands

Measuring stands, also known as metrology stands or inspection

stands, are tools used to securely hold and position measuring instruments for

accurate and precise measurements. These stands provide stability and eliminate

the need for the user to hold the measuring instrument, allowing for consistent

and repeatable measurements. Measuring stands are commonly used in

laboratories, quality control departments, machining facilities, and other

environments where precise measurements are required. Here are some common

types of measuring stands:

1.

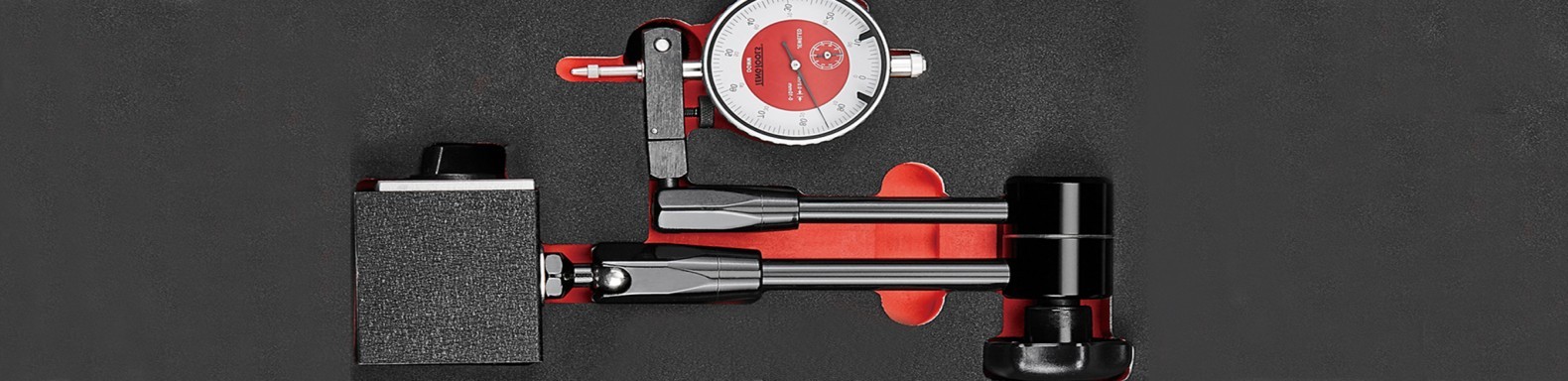

Magnetic Base Stands: Magnetic base stands are versatile stands

that use a magnetic base to secure the stand to a ferrous metal surface. They

typically have an adjustable arm or column that holds the measuring instrument,

such as a dial indicator or test indicator. The magnetic base provides a strong

grip and allows for easy repositioning of the stand.

2.

Benchtop Stands: Benchtop stands are sturdy stands designed to

be placed on a workbench or flat surface. They have a solid base and an

adjustable column or arm that holds the measuring instrument. Benchtop stands

provide stability and precise positioning for accurate measurements.

3.

Height Stands: Height stands, also known as height gauges or

surface plate stands, are specialized stands used for measuring the height of

objects. They consist of a vertical column with a measuring arm or probe that

can be raised or lowered. Height stands often have a fine adjustment mechanism

to achieve precise measurements.

4.

Optical Comparator Stands: Optical comparator stands are

designed specifically for holding optical comparators, which are used for

measuring dimensions and inspecting the shape and profile of objects. These

stands have a stable base and an adjustable arm or stage that holds the optical

comparator at the desired position.

5.

Gage Stand: Gage stands, also called gauge stands, are used to

hold various types of gauges, such as thread gauges, ring gauges, or plug

gauges. They provide a secure and convenient way to position the gauge for accurate

measurements.

6.

Portable Stands: Portable measuring stands are lightweight and

designed for easy transportation. They often have foldable or collapsible

components, allowing them to be easily carried to different locations. Portable

stands are suitable for field measurements or situations where mobility is

required.

7.

Multi-Axis Stands: Multi-axis stands are designed to provide

precise positioning in multiple axes. They often have adjustable columns or

arms that allow for movement in multiple directions, such as horizontal,

vertical, and rotational adjustments. Multi-axis stands are useful for complex

measurement setups or when measurements need to be taken from different angles.

These are just a few examples of measuring stands. The choice of

stand depends on the specific measurement requirements and the type of

measuring instrument being used. It's important to select a stand that offers

stability, adjustability, and compatibility with the measuring instrument to

ensure accurate and reliable measurements.

-PhotoRoom.jpg)