Hole, Drill & Wire Gauges

Hole, drill, and wire gauges are specialized measuring tools used to determine the sizes of holes, drill bits, and wires. They are commonly used in industries such as machining, manufacturing, automotive, electrical, and telecommunications. Here's an overview of each type of gauge:

Hole Gauges (Bore Gauges): Hole gauges, also known as bore gauges or telescopic gauges, are used to measure the internal diameter of holes or bores. They typically consist of two or more telescoping rods or cylinders that can be adjusted to fit the size of the hole. The gauge is inserted into the hole, and the rods are expanded until they make contact with the hole walls. The measurement is then read from the scale on the gauge.

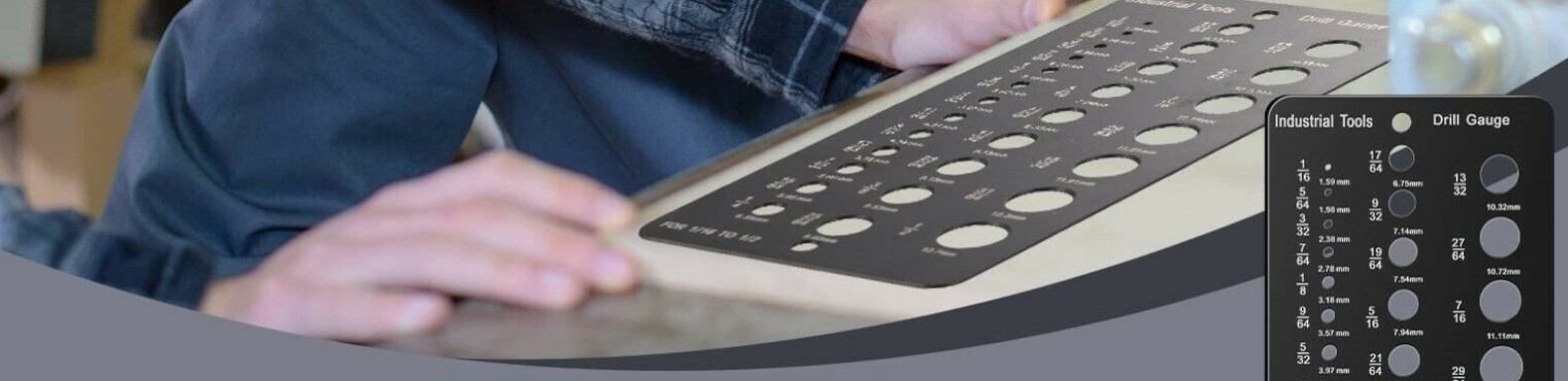

Drill Gauges (Drill Bit Gauges): Drill gauges, also called drill bit gauges or drill size gauges, are used to determine the size or diameter of drill bits. They have a range of holes or slots of different sizes that correspond to standard drill bit sizes. By inserting a drill bit into the appropriate hole or slot on the gauge, the user can quickly identify the size of the bit. This is particularly useful when selecting the correct drill bit for a specific application or verifying the size of an existing drill bit.

Wire Gauges (Wire Diameter Gauges): Wire gauges, also known as wire diameter gauges or wire thickness gauges, are used to measure the diameter or thickness of wires or other cylindrical objects. They typically consist of a set of notches or slots of different sizes that correspond to specific wire gauges or thicknesses. The wire is inserted into the appropriate slot until it fits snugly, and the corresponding wire gauge or thickness is read from the gauge. Wire gauges are commonly used in electrical and telecommunications industries to verify wire thickness and ensure compliance with standards.

These gauges provide quick and accurate measurements for holes, drill bits, and wires, allowing users to select the appropriate sizes or verify the dimensions of existing components. They are essential tools for maintaining precision and quality in various applications. Proper care and storage of these gauges are important to preserve their accuracy and extend their lifespan.

-PhotoRoom.jpg)