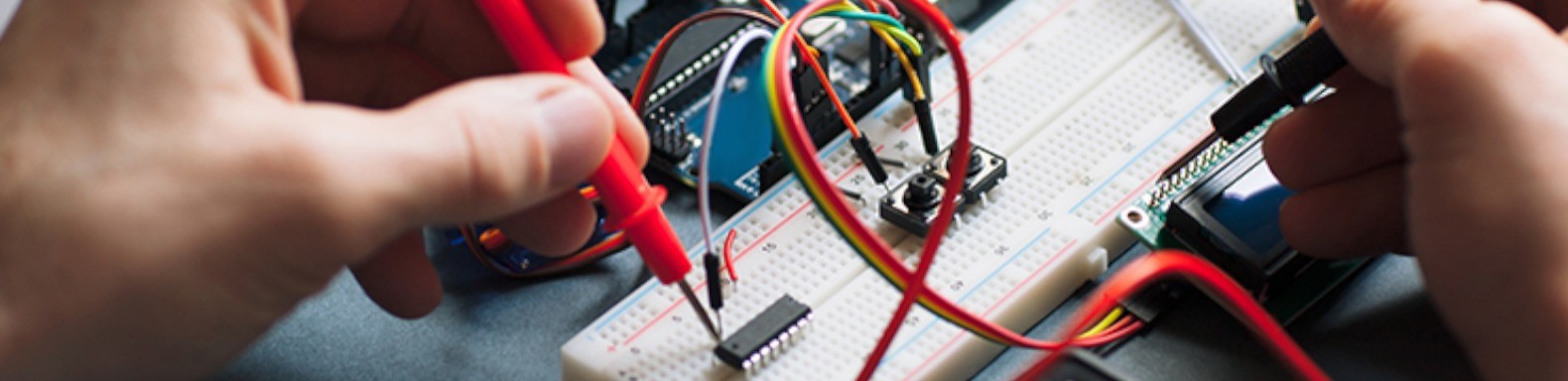

Electrical Testing

Categories

Electrical

testing refers to the process of assessing the electrical characteristics and

performance of electrical components, systems, or equipment. It involves using

various instruments and techniques to measure, analyze, and verify electrical

parameters to ensure safety, functionality, and compliance with standards. Here

are some common electrical testing methods:

1. Voltage Testing: Voltage testing involves measuring the voltage level in

electrical circuits to verify proper operation, identify potential issues, or

ensure compliance with specified voltage ranges.

2. Current Testing: Current testing is performed to measure the flow of

electric current in a circuit. It helps in assessing the load, detecting

faults, and ensuring proper functioning of electrical systems.

3. Resistance Testing: Resistance testing is used to measure the resistance

of electrical components or conductors. It helps identify faulty or damaged

components and ensures the desired resistance values are met.

4. Continuity Testing: Continuity testing is performed to check the

integrity of electrical connections and determine if there is a continuous path

for electric current flow. It is commonly used to identify open circuits or

faulty wiring.

5. Insulation Testing: Insulation testing is conducted to assess the

insulation resistance of electrical insulation materials or systems. It helps

detect insulation breakdown, leaks, or weaknesses that could lead to electrical

hazards or malfunctions.

6. Grounding Testing: Grounding testing ensures the effectiveness of

electrical grounding systems. It verifies the resistance between the grounding

system and the earth, ensuring proper safety and protection against electrical

faults.

7. Power Quality Testing: Power quality testing involves analyzing various

aspects of electrical power, such as voltage fluctuations, harmonics, power

factor, and transient events. It helps diagnose power quality issues that can

affect equipment performance and electrical system efficiency.

8. Protective Device Testing: Protective device testing includes testing

circuit breakers, fuses, relays, and other protective devices to ensure they

operate correctly during fault conditions and provide proper protection to the

electrical system.

9. Infrared Thermography: Infrared thermography uses thermal imaging cameras

to identify temperature variations in electrical components and systems. It

helps detect hotspots, loose connections, or overloaded circuits that may

indicate potential failures or hazards.

Electrical testing is crucial for ensuring the safety,

reliability, and efficiency of electrical systems and equipment. It is

typically performed by trained technicians or engineers using specialized

electrical testing instruments and following relevant industry standards and guidelines.

Regular testing and maintenance help prevent electrical failures, reduce

downtime, and ensure optimal performance of electrical systems.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

-PhotoRoom.jpg)