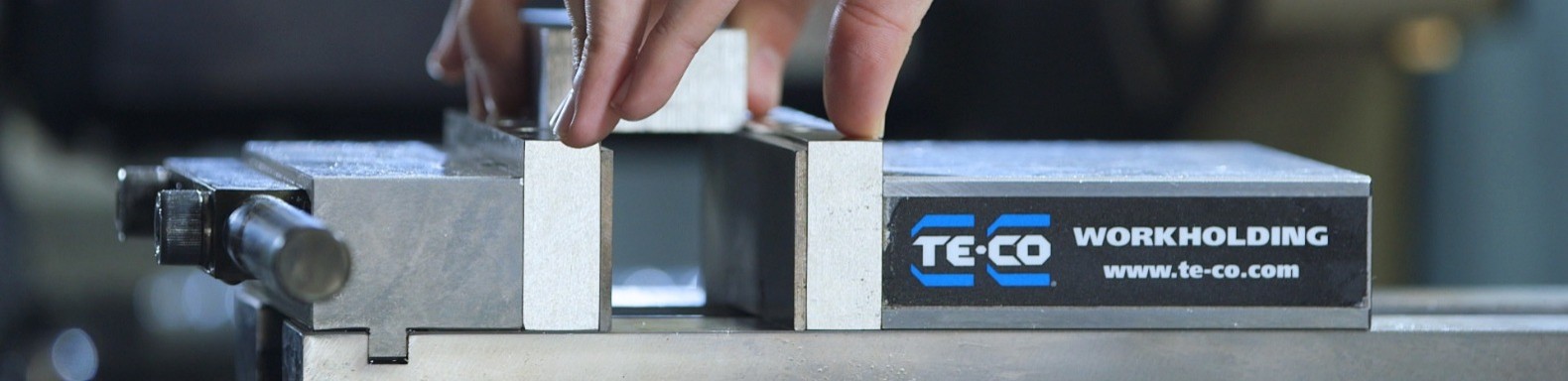

Adjustable parallel

An adjustable

parallel, also known as an adjustable parallel set or parallel bar set, is a

precision measuring tool used in machining and manufacturing processes. It

consists of a set of parallel bars or plates that can be adjusted in height to

provide precise and accurate spacing between two surfaces or workpieces. The

adjustable parallel set typically includes a number of parallel bars of

different sizes.

Here are some key features and uses of adjustable

parallels:

1. Adjustable Height: The main feature of adjustable parallels is the

ability to adjust the height of the parallel bars. This allows for precise

alignment and spacing between workpieces or machine parts.

2. Parallelism: The parallel bars in the set are manufactured to high

accuracy and maintain parallelism with each other. This ensures consistent

spacing and alignment across the entire set.

3. Measurement: Adjustable parallels are often used in conjunction with

other measuring tools such as calipers or micrometers to measure and set

precise distances between surfaces or workpieces.

4. Workpiece Support: Adjustable parallels can be used to support workpieces

during machining or inspection processes. They provide a stable and leveled

surface for accurate measurements and machining operations.

5. Machine Setup: Adjustable parallels are commonly used in machine setups

to align and position workpieces or tooling. They help ensure that the

workpiece is positioned correctly and parallel to the machine's axes.

6. Versatility: Adjustable parallels can be used in various machining

operations, including milling, drilling, grinding, and inspection. They are

suitable for both manual and CNC machining applications.

7. Durability and Material: Adjustable parallels are typically made from

hardened steel or other high-quality materials to ensure durability and

precision. Some sets may also have a surface treatment or coating for corrosion

resistance.

Adjustable parallels are valuable tools in precision

machining and manufacturing industries, allowing for accurate measurements,

alignment, and setup of workpieces. They provide flexibility and precision in

achieving parallelism and consistent spacing, contributing to high-quality and

precise machining operations.

-PhotoRoom.jpg)