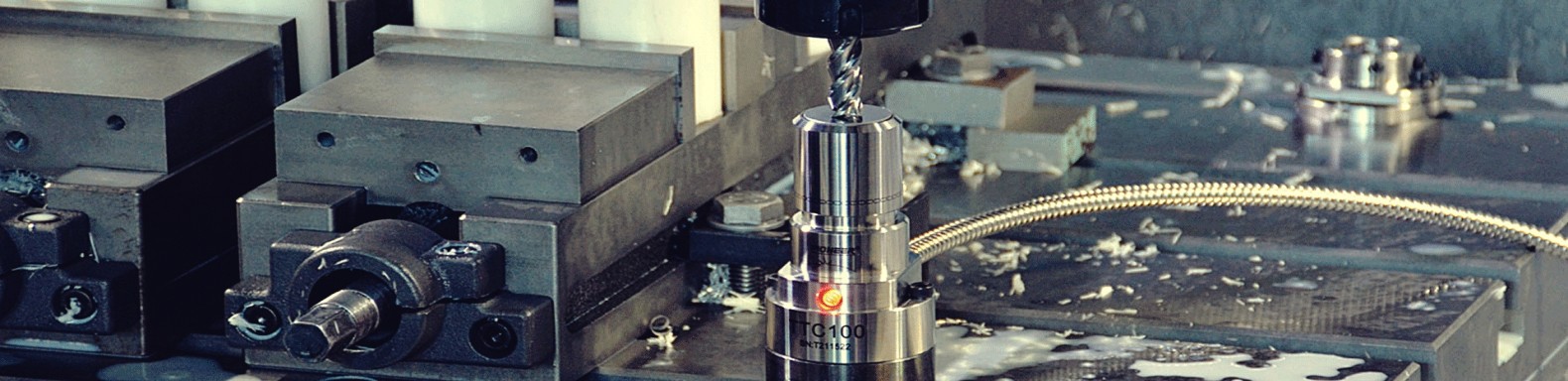

0 Setters

"Zero Setters" in the context of machining and CNC (Computer Numerical Control) operations. Zero Setters, also known as edge finders or work offset setters, are tools used to accurately set the origin or reference point (zero position) on a CNC machine. Here's some information about Zero Setters:

Purpose: Zero Setters are used to establish the precise position of the machine's axes relative to the workpiece or tool. By accurately setting the zero position, the CNC machine can accurately position and move the cutting tool or workpiece during machining operations.

Construction: Zero Setters typically consist of a cylindrical body with a spring-loaded mechanism inside. They have a shank that fits into the machine's spindle and a probe that extends from the body. The probe is usually made of a conductive material and is used to make contact with the workpiece or the edge of a work holding fixture.

Operation: To use a Zero Setter, the machine operator places the workpiece or work holding fixture on the machine's table. The Zero Setter is inserted into the machine's spindle, and the spindle is lowered until the probe of the Zero Setter touches the surface or edge of the workpiece or fixture. At this point, the operator sets the machine's coordinate system to establish the zero position. This is typically done by inputting the tool length offset or work offset values into the CNC machine's control panel.

Accuracy: Zero Setters are designed to provide precise measurements for setting the zero position. They are capable of accurately locating the edges or surfaces of the workpiece with a high degree of repeatability. The accuracy of Zero Setters depends on various factors, including the quality of the tool itself, the machine's spindle runout, and the skill of the operator.

Advantages: Zero Setters offer several advantages in CNC machining operations. They allow for quick and accurate zero point setup, reducing the time required for alignment and setup tasks. They also minimize the risk of human error in determining the zero position, leading to improved machining accuracy and consistency.

Zero Setters are essential tools for CNC machining operations, particularly in precision manufacturing and machining tasks. They streamline the setup process and contribute to achieving accurate and repeatable results. Different types and sizes of Zero Setters are available to accommodate various machine spindle sizes and workpiece geometries.

-PhotoRoom.jpg)