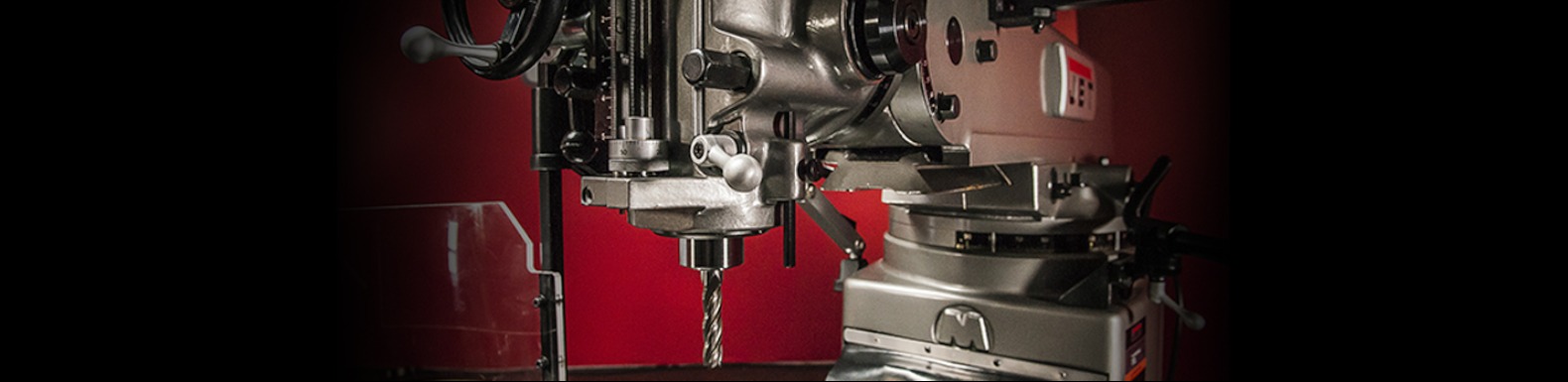

Vertical Milling Machines

Vertical milling machines are a type of milling machine where the spindle axis is vertically oriented. They are commonly used in machining operations to remove material from a workpiece using rotary cutters. Vertical mills are highly versatile and widely used in various industries, including manufacturing, metalworking, and fabrication. Here are some key aspects and features of vertical milling machines:

1. Spindle Orientation: In vertical milling machines, the spindle is positioned vertically, perpendicular to the worktable. This vertical orientation allows for easier and more precise cutting operations, especially when working with complex shapes or deep cuts.

2. Worktable: The worktable is a flat surface where the workpiece is secured during milling operations. It can be moved in multiple axes to position the workpiece accurately. Vertical milling machines typically have a large and sturdy worktable, which can be tilted or rotated to enable angular or compound cuts.

3. Spindle Speed and Power: Vertical milling machines feature a spindle that rotates at high speeds. The spindle speed can be adjusted to accommodate different cutting requirements, such as varying materials or cutter sizes. These machines are available in various power capacities, allowing for efficient material removal and handling heavier workpieces.

4. Tooling and Accessories: Vertical mills use a variety of cutting tools, such as end mills, face mills, and drills, to remove material from the workpiece. The cutting tools are mounted in a spindle, and the workpiece is moved against them to create the desired shape or cut. Additionally, vertical milling machines can be equipped with tool changers, automatic feeds, digital readouts (DROs), and other accessories to enhance productivity and ease of operation.

5. Versatility: Vertical milling machines offer versatility in terms of the types of operations they can perform. They can be used for a wide range of tasks, including face milling, end milling, drilling, boring, and tapping. With the appropriate tooling and accessories, vertical mills can accommodate complex machining operations and produce intricate parts.

6. CNC Vertical Mills: Many modern vertical milling machines are equipped with computer numerical control (CNC) systems. CNC vertical mills are programmable, allowing for automated and precise machining operations. They can execute complex machining tasks, follow intricate designs, and produce consistent and accurate results.

Vertical milling machines are popular due to their versatility, precision, and efficiency in a variety of machining applications. However, it is important to adhere to proper safety protocols, wear appropriate personal protective equipment, and receive proper training when operating these machines to ensure safe and efficient operation.

.jpg)