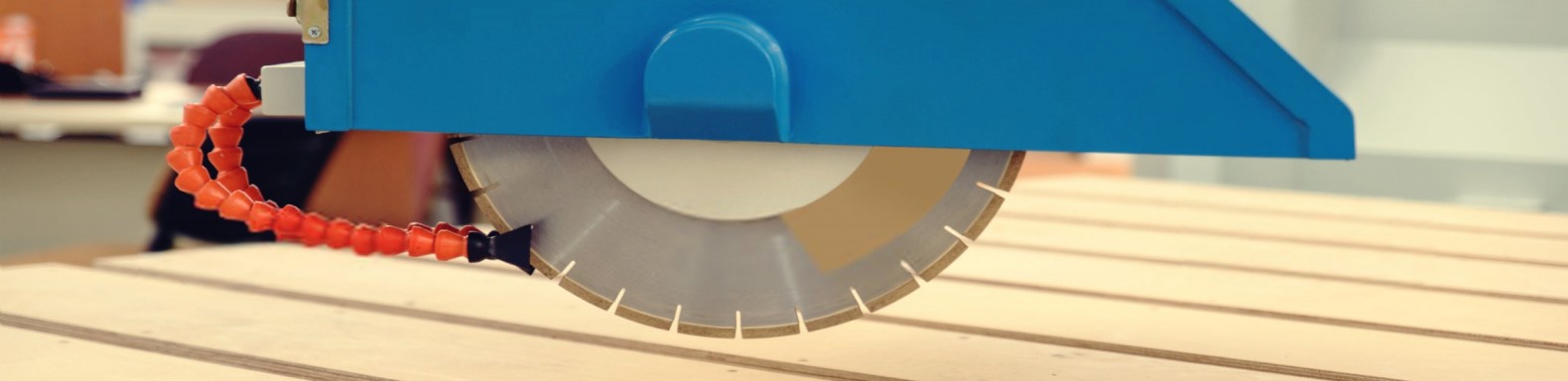

Diamond Saw Blades

Diamond saw blades are cutting tools used in various industries, including construction, stone fabrication, and metalworking. They are specifically designed for cutting hard and abrasive materials such as concrete, asphalt, stone, ceramics, and metals. Diamond saw blades utilize synthetic diamond crystals embedded in a metal matrix to provide superior cutting performance and durability.

Here are some key features and characteristics of diamond saw blades:

Diamond Segments: Diamond saw blades consist of a circular steel core with diamond segments attached to the outer edge. The diamond segments contain synthetic diamond crystals, which are the cutting elements of the blade. The segments can vary in shape, size, and arrangement depending on the application and the type of material being cut.

Blade Types: Diamond saw blades come in various types, including continuous rim blades, segmented blades, turbo blades, and laser-welded blades. Each type has its own specific design and cutting characteristics, making them suitable for different materials and cutting tasks. Continuous rim blades provide smooth cuts, segmented blades offer faster cutting speeds, turbo blades have enhanced cooling and debris removal, and laser-welded blades provide increased durability.

Bond Types: The diamond segments are bonded to the steel core using different types of bonding materials. The bond type affects the performance and lifespan of the blade. Common bond types include soft bond, medium bond, and hard bond. Softer bonds are suitable for cutting hard materials, while harder bonds are preferred for cutting soft materials. The bond type also determines the blade's resistance to wear and heat generated during cutting.

Blade Diameter and Arbor Size: Diamond saw blades are available in various diameters, ranging from small blades for handheld tools to large blades for industrial saws. The blade diameter should be selected based on the depth and size of the cuts required. Additionally, diamond saw blades have an arbor hole in the center that fits onto the saw's arbor or spindle. The arbor size of the blade should match the arbor size of the saw for proper fit and attachment.

Cutting Performance: Diamond saw blades offer exceptional cutting performance, allowing for precise and efficient cuts in hard materials. The synthetic diamond crystals on the blade's edge are extremely hard and abrasion-resistant, enabling them to effectively cut through the material. The design and quality of the diamond segments, along with the appropriate blade type and bond, contribute to the overall cutting performance.

Cooling and Lubrication: During cutting, diamond saw blades generate heat and debris. It's important to ensure proper cooling and lubrication to prevent overheating and extend the blade's lifespan. Water is commonly used as a coolant and lubricant when cutting with diamond saw blades. Wet cutting helps to control temperature, flush away debris, and provide smoother cuts.

Diamond saw blades are versatile cutting tools suitable for a wide range of applications. They offer long-lasting performance, high cutting speeds, and clean cuts in hard and abrasive materials. It's important to choose the right type and size of diamond saw blade based on the specific material and cutting requirements. Proper use, maintenance, and adherence to safety precautions are necessary for optimal performance and safety during operation.