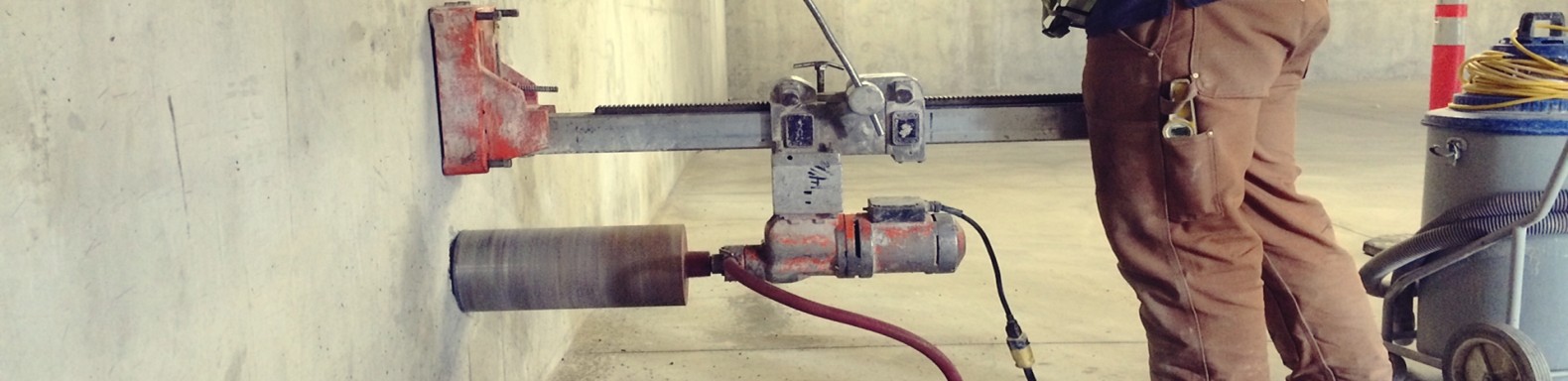

Core Drills Machines

Hammer drills and rotary hammers are powerful tools used for drilling into hard materials such as concrete, stone, and masonry. While they serve a similar purpose, there are some differences between hammer drills and rotary hammers. Let's explore each tool:

Hammer Drills: Hammer drills, also known as percussion drills, are versatile tools that combine drilling and hammering actions. They feature a special mechanism that delivers rapid, short, and powerful impacts in addition to the rotational drilling motion. Here are some key features of hammer drills:

Drilling and Hammering: Hammer drills have a switch or mode selector that allows you to choose between drilling-only mode, hammering-only mode, or a combined drilling and hammering mode. In the combined mode, the drill bit rotates while the hammer mechanism delivers impacts to break up the material being drilled.

Versatility: Hammer drills are suitable for drilling holes in various materials, including wood, metal, plastic, and masonry. They are commonly used in construction and DIY projects where occasional drilling into masonry is required.

Light to Medium Duty: Hammer drills are generally suitable for light to medium-duty drilling tasks. While they can handle drilling into concrete and masonry, their impact force is typically lower than that of rotary hammers.

Rotary Hammers: Rotary hammers, also known as rotary hammer drills, are heavy-duty tools specifically designed for drilling into hard materials like concrete, stone, and masonry. They are more powerful and efficient compared to hammer drills. Here are some key features of rotary hammers:

Hammering Mechanism: Rotary hammers utilize a piston mechanism that delivers a powerful hammering action to the drill bit. The piston rapidly moves back and forth, generating a high impact force that helps break up the material being drilled.

Three Modes: Rotary hammers typically have three modes: drilling-only mode, hammering-only mode, and a combined drilling and hammering mode. In the combined mode, the tool both rotates and delivers hammering impacts for effective drilling in hard materials.

Heavy-Duty Performance: Rotary hammers are designed for heavy-duty applications. They can easily drill through concrete, masonry, and other tough materials with greater speed and efficiency compared to hammer drills.

Vibration Damping: Rotary hammers often feature vibration damping systems or handles that help reduce the transfer of vibrations to the user's hands and arms. This improves comfort and reduces fatigue during extended use.

Available in Corded and Cordless: Rotary hammers are available in both corded and cordless models. Corded rotary hammers offer consistent power, while cordless models provide more mobility but may have slightly less power due to battery limitations.

Rotary hammers are commonly used in construction, remodeling, and other professional settings where frequent drilling into concrete and masonry is required. They excel at drilling larger and deeper holes and are more efficient in tough materials compared to hammer drills.

When using either hammer drills or rotary hammers, it's important to wear appropriate personal protective equipment (PPE), such as safety goggles, gloves, and hearing protection. Follow the manufacturer's instructions and ensure that you select the right drill bit for the material you are drilling.

In summary, hammer drills are versatile tools suitable for occasional drilling into masonry, while rotary hammers are heavy-duty tools specifically designed for drilling into hard materials like concrete and masonry. The choice between the two depends on the nature of your drilling tasks and the level of power and performance required.